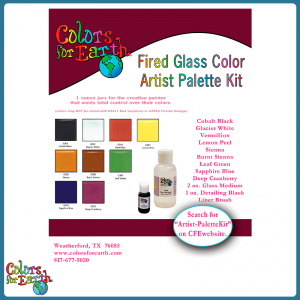

Glass Enamels

Download a copy of “Glass Color Basics” PDF

Download NEW Color Flyer as shown above. These are large files so it may take a while to download the PDF. They are listed in the order you see them above.

Glass 2018 Pg. 5

Glass 2018 Pg. 6

Glass 2018 Pg. 1

Glass 2018 Pg. 2

Glass 2018 Pg. 3

Glass 2018 Pg. 4

CFE Enamels can be used on 90 coe, 96 coe, float, and wine bottles. The minimum temperature is 1380 degrees but a full fuse is recommended.

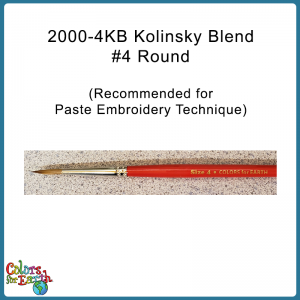

“G Series”

The “G” series are glossy glass colors that are in a powder formula that is mixed with our GM300 Glass Color Medium. By mixing with the medium it will insure an opaque glossy finish. Mix to a “white glue” or heavy cream consistency for opaque coverage. Two colors can be mixed together to achieve another color.

- The 39 of the colors are lead-free (non-toxic).

- Available in 1 oz. (25 grams), 2 oz.,4 oz. and Pint jars.

- We have 3 colors in the “GT” Series that are not food safe and should not be used on any food surface items.

- They DO NOT have to be capped to have a glossy finish.

- When the colors are thinned they can be brushed, sponged, sprayed/airbrushed, stippled or applied with an airpen, writer bottle or gizmo or used with a stencil. When thinned with GM300 Glass Medium you retain the color. When thinned with water you dilute the color.

- When painting with the colors it is recommended to use a “drop & fill”, “pool and puddle” method with a liner brush and then push and pull into areas.

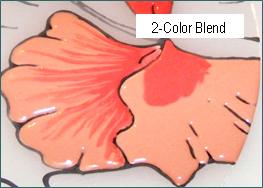

- A two-color blend of colors is done by butting two colors next to each other and then pulling one color through the other, back and forth.

- Marbleizing can be done by taking 1-3 colors and placing dots of each color in an area until it is filled and then on the top surface creating a figure “8” or “S” with the brush to variegate the colors through each other.

- Keep the colors mixed up as the color tends to settle to the bottom.

- The colors can be used dry. Example; Sifted/Sprinkled over the glass for different techniques.

- It can be silk screened.

- Firing is cone 014-017 or from 1376º to 1550º in a ceramic or a glass kiln, depending on the type of glass you are using. Our glass colors hold their color to a much higher temperature when used on ceramic or porcelain bisque.

- It can be added to Flexi-Glass Medium to create sheets of flexible glass color.

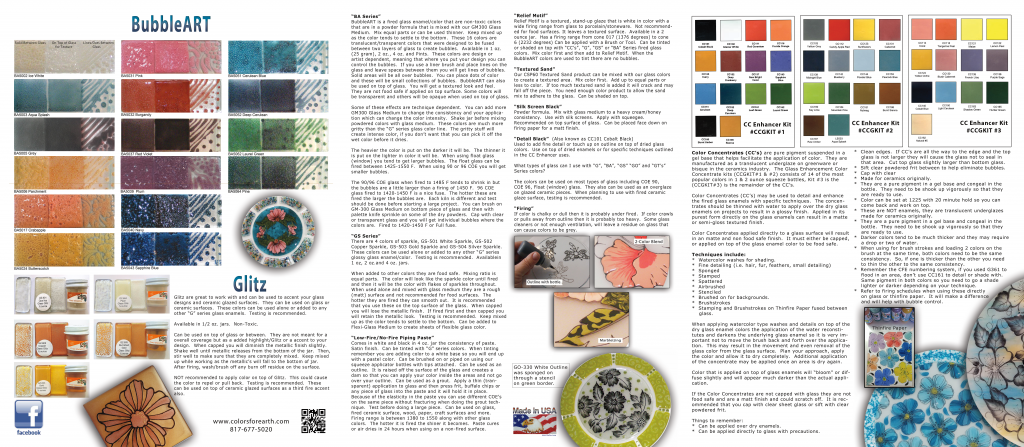

“BA Series”

- BubbleART is a fired glass color that is non-toxic colors that are in a powder formula that is mixed with our GM300 Glass Medium. Mix equal parts or can be used thinner. Keep mixed up as the color tends to settle to the bottom.

- These 16 colors are translucent/transparent colors that were designed to be fused between two layers of glass to create bubbles.

- Available in 1 oz. (25 gram), 2 oz., 4 oz. and Pints.

- These colors are design or artist dependent, meaning that where you put your design you can control the bubbles. If you use a liner brush and place lines on the glass and leave spaces between them you will get lines of bubbles. Solid areas will be all over bubbles. You can place dots of color and these will be small collections of bubbles.

- BubbleART can also be used on top of the glass. You will get a textured look and feel. Some colors will be transparent and others will be opaque when used on top of the glass. Some of these effects are technique dependent. You can add more GM300 Glass Medium to change the consistency and your application which can change the color intensity. They are not food safe if applied on the top surface.

- Shake jar before mixing powdered colors with glass medium. These colors are much more gritty than the “G” series glass color line. The gritty stuff will create intense color if you don’t want that you can pick it off the wet color before it dries.

- The heavier the color is put on the darker it will be. The thinner it is put on the lighter in color it will be.

- When using float glass (window) you tend to get larger bubbles. The float glass can be fired between 1425-1550 F.

- When using 90 or 96 COE you will get smaller bubbles. The 90/96 COE glass, when fired to 1485 F, tends to shrink in but the bubbles are a little larger than a firing of 1450 F. 96 COE glass fired to 1420-1450 F is a nice fuse.

- The hotter these are fired the larger the bubbles are. Each kiln is different and a test should be done before starting a large project.

- You can brush on GM-300 Glass Medium on the bottom piece of glass and then with palette knife sprinkle on some of the dry powders. Cap with clear or transparent glass and you will get individual bubbles where the colors are. Fired to 1420-1450 For Full fuse.

“GS Series”

There are 4 colors of sparkle, GS-501 White Sparkle, GS-502 Copper Sparkle, GS-503 Gold Sparkle, and GS-504 Silver Sparkle.

- These colors can be used alone or added to any other “G” series glossy glass color. Testing is recommended.

- Available in 1 oz, 2 oz. and 4 oz. jars.

- When added to other colors they are food safe. The mixing ratio is equal parts. The color will look like the sparkle color until fired and then it will be the color with flakes of sparkles throughout.

- When used alone and mixed with glass medium they are a rough(matt) surface and not recommended for food surfaces. The hotter they are fired they can smooth out. It is recommended that you use these on the top surface of the glass.

- When capped you will lose the metallic finish.

- If fired first and then capped you will retail the metallic look. Testing is recommended.

- Keep mixed up as the color tends to settle to the bottom.

- It can be added to Flexi-Glass Medium to create sheets of flexible glass color.

Relief Motif

Relief Motif is a textured, stand-up glaze that is white in color with a wide firing range from glass to porcelain/stoneware.

- Not recommended for food surfaces. It leaves a textured surface.

- Available in a 2-ounce jar.

- Has a firing range from cone 017 (1376 degrees) to cone 6 (2232 degrees)

- It can be applied with a Brush or Tool.

- Can be tinted or shaded on top with “G”, “GS” or “BA” Series fired glass colors. Mix color first and then add to Relief Motif. The pink flower on the right was tinted with BA5031 BubbleART Pink.

“GO” Series

The “GO” series is our glass outline colors. These are liquid and ready to use straight from the bottle.

- Available in 1 oz, 2 oz and 8 oz. squeeze bottles

- Black and White are available.

- They are matt in the finish. They can be pre-fired and then capped to make a glossy finish.

- Attach Lure-Lock cap and different size tips to write an outline with.

- It can be applied with a brush, sponge or writer bottle.

Low-Fire/No-Fire Piping Paste

- It comes in white and black in 4 oz. jar the consistency of paste.

- Satin finish.

- It can be tinted with “G” series colors. When tinting remember you are adding color to a white base so you will end up with a pastel color.

- It can be brushed on or piped on using our squeeze applicator bottles with tips attached.

- It can be used as an outline. It is raised off the surface of the glass and creates a dam so that you can apply your color inside the areas and not go over your outline.

- It can be used as a grout. Apply a thin (transparent) application to glass and then press frit, buffalo chips, or any piece of glass into the paste and it will hold it in place. Because of the elasticity in the paste, you can use different COE’s on the same piece without fracturing when doing the grouting technique. Test before doing a large piece.

- It can be used on glass, fired ceramic surface, wood, paper, craft surfaces, and more.

- The firing range is between 1380 to 1550 along with other glass colors. The hotter it is fired the shiner it becomes.

- Paste cures or air dries in 24 hours when using on a non-fired surface.

“GT Series”

These colors are leaded and not recommended for food surfaces.

- Kiln needs to be well vented.

- If using a kiln that has had other things in it besides glass, such as copper-based glazes and materials it could affect the outcome of the colors. They may turn grey or smoky looking.

- Apply for even coverage.

- Allow it to dry before firing.

Textured Sand

Our CSP60 Textured Sand product can be mixed with our glass colors to create a textured area.

- Mix color first.

- Add up to equal parts or less to color.

- If too much-textured sand is added it will crack and may fall off the piece. You need enough color product to allow the sand mix to adhere to the glass.

- It can be shaded on top.

Silk Screen Black

- Powder formula.

- Mix with glass medium to a heavy cream/peanut butter consistency.

- Use with silkscreens.

- Apply with a squeegee.

- Recommended on the top surface of the glass.

- It can be placed face down on firing paper for a matt finish.

Detail Black

- Used to add fine detail or touch upon outline on top of dried glass colors.

- Do NOT use on glass. Use on top of dried color only.

- What types of glass can I use with “G”, “BA”, “GS” “GO” and “GT’s” Series colors?

- The colors can be used on most types of glass including:

- COE 90

- COE 96

- Float (window) glass.

- They also can be used as an overglaze on glazed ceramic pieces. When planning to use with fired ceramic glaze surface, testing is recommended.

Firing

- If the color is chalky or dull then it is probably underfired.

- If color crawls or pulls away from outline then it is probably too heavy.

- Some glass cleaners or not enough ventilation will leave a residue on the glass that can cause colors to be grey.